View Our Full Information Sheet

WHAT IS LEED?

The LEED™ (Leadership in Energy and Environmental Design) Green Building Rating System is a voluntary, consensus-basedprogram for developing high-performance, sustainable buildings. These LEED standards have been developed by the U.S. GreenBuilding Council (www.usgbc.org). Based on well-founded scientific standards, LEED emphasizes state-of-the-art strategiesfor sustainable site development, water savings, energy efficiency , materials selection and indoor environmental quality. Using MagnumStone™ in a building project may help one achieve LEED Credits.

MAgnuMSTonE™ MArkETIng MATErIALS

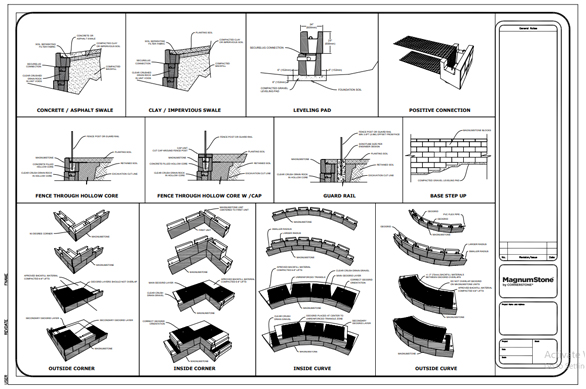

Installation

guide

Sustainability Brochure

general

Brochure

Dimensional Coping

Positive Connection

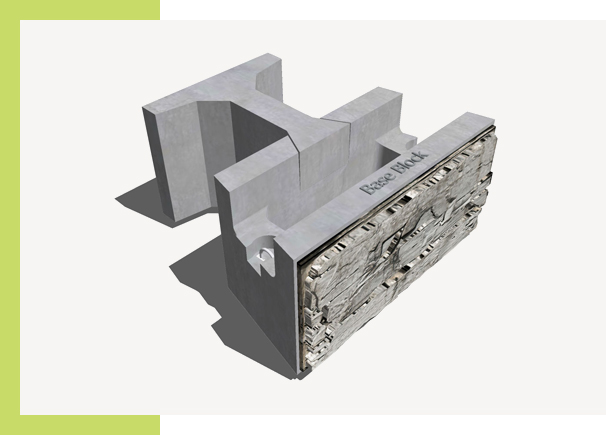

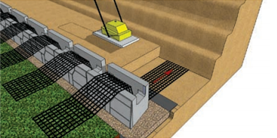

Step 01

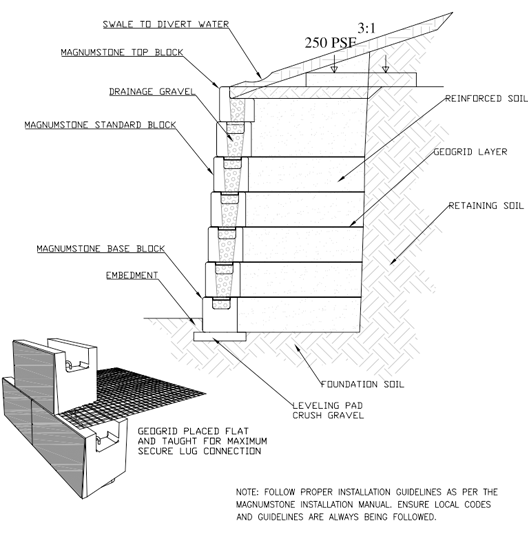

Lay first course

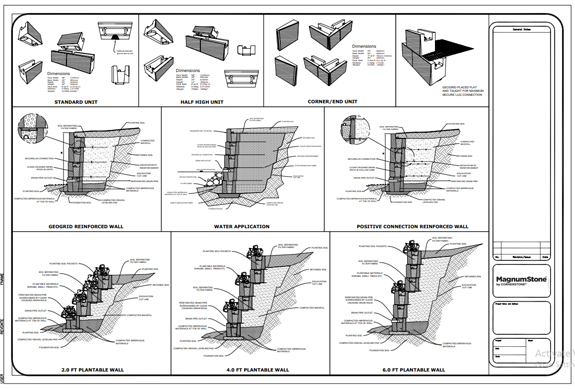

Geogrid positive reinforcement will be cut in24″ wide strips and twice the length specifiedin the design plus 2′ for the unit height. (ifspecified Geogrid length is 10′ the length will be 22′ long)

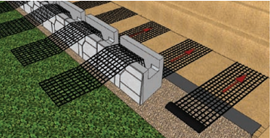

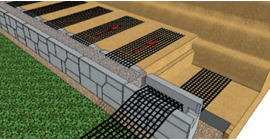

Step 02

compact BackfiLL

Backfill and compact the Reinforced Zone by placing materials from the back of the wall towards the end of the Geogrid. Install and compact Backfill Materials in 8″ Lifts

Step 03

Wrap geogrid

Pull rolled Geogrid out of the vertical core and place perpendicular to top of first unit on top of compacted backfill. Tension Geogrid before installing drainage gravel. Install the Clear Crush Drain Gravel 2″ below the top of units to allow for Securelug connection

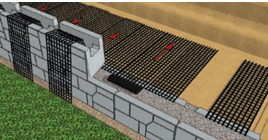

Step 04

Lay second course

Place the second MagnumStone™ unitsvertical open core over the second layer of half rolled Geogrid. Make sure Geogrid is placed to the correct design length perpendicular to the unit and centered to the two adjacent Geogrid strips before placing the unit

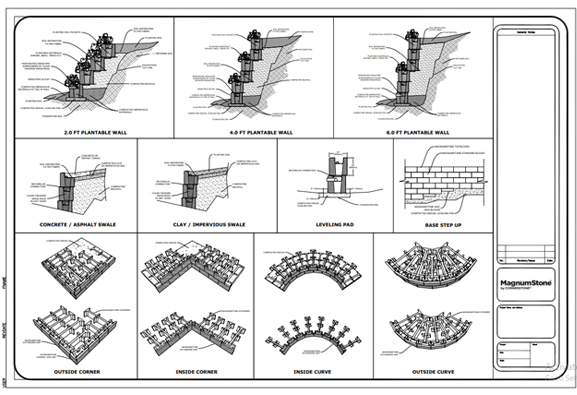

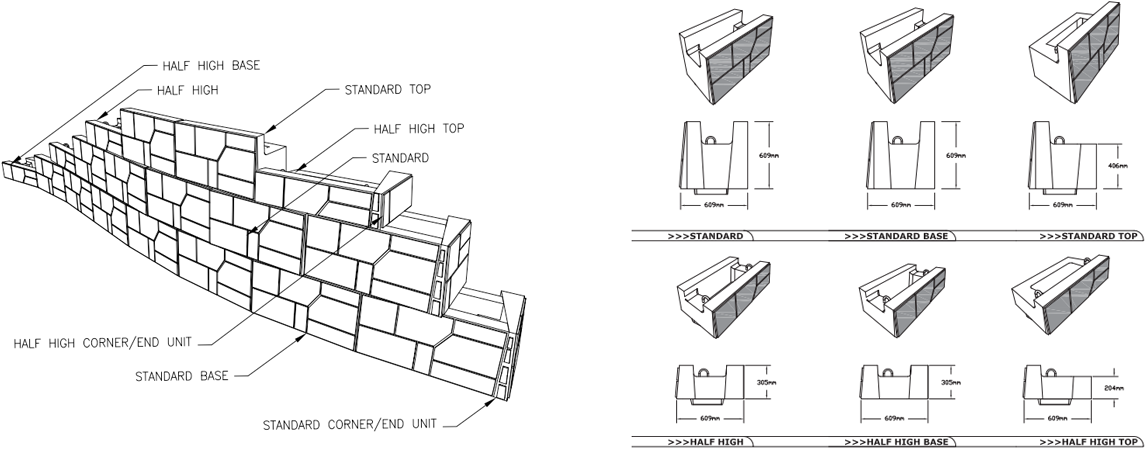

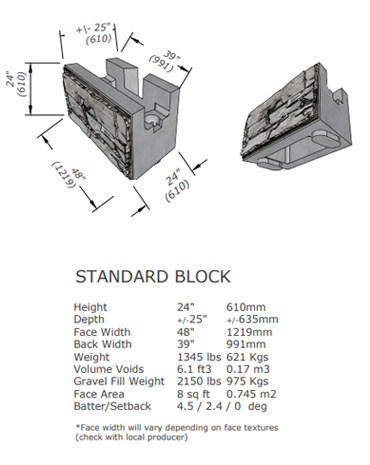

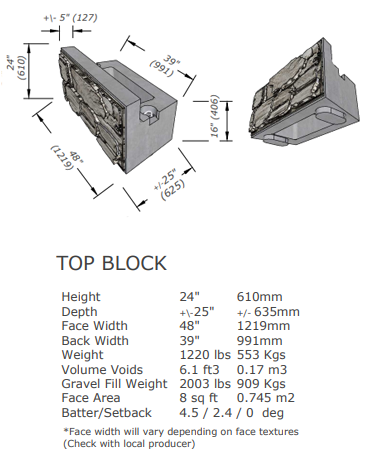

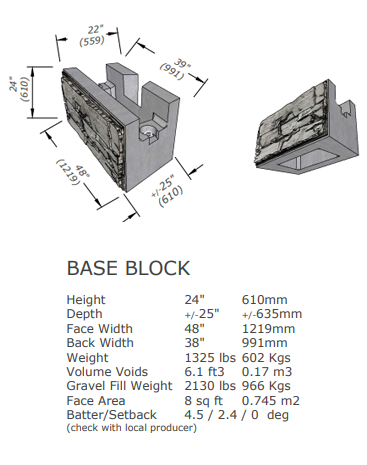

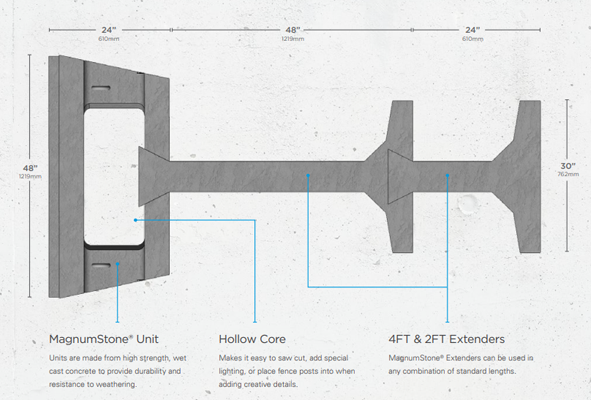

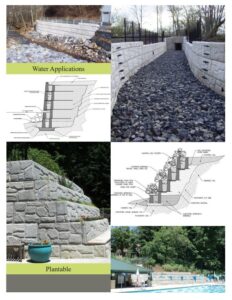

Our MagnumStone™ product is a large block

hollow core, wet-cast segmental retaining wall system that uses nearly half the amount of concrete per face foot when compared to traditional solid systems. The environmental and economical advantages of the pre-cast hollow block MagnumStone™ product are unprecedented in the retaining wall industry. Because of its size and design flexibility, MagnumStone™ is ideal for almost any retaining wall project from residential to large commercial installations.

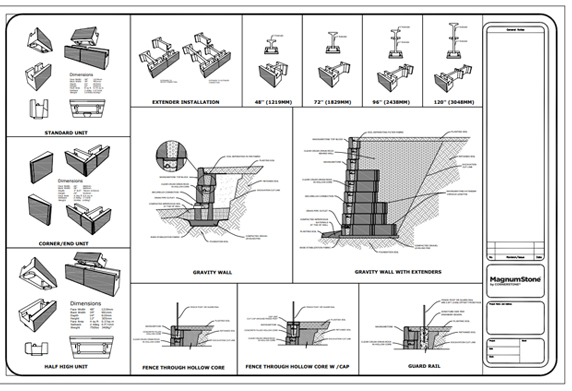

Unit to unit connection uses our patented, mortarless, SecureLug™ interlock system (no expensive, time consuming pins or clips.) and are light enough that they can be moved two at a time with lighter machinery such as a standard Bobcat.

A wet cast segmental retaining wall product provides freeze/thaw durability advantages over competing products, a critical factor for the Departments Of Transport work that MagnumStone™ is very well suited for. The wet-cast process also allows for unique through-wall applications, face options and logo details for any type of project.

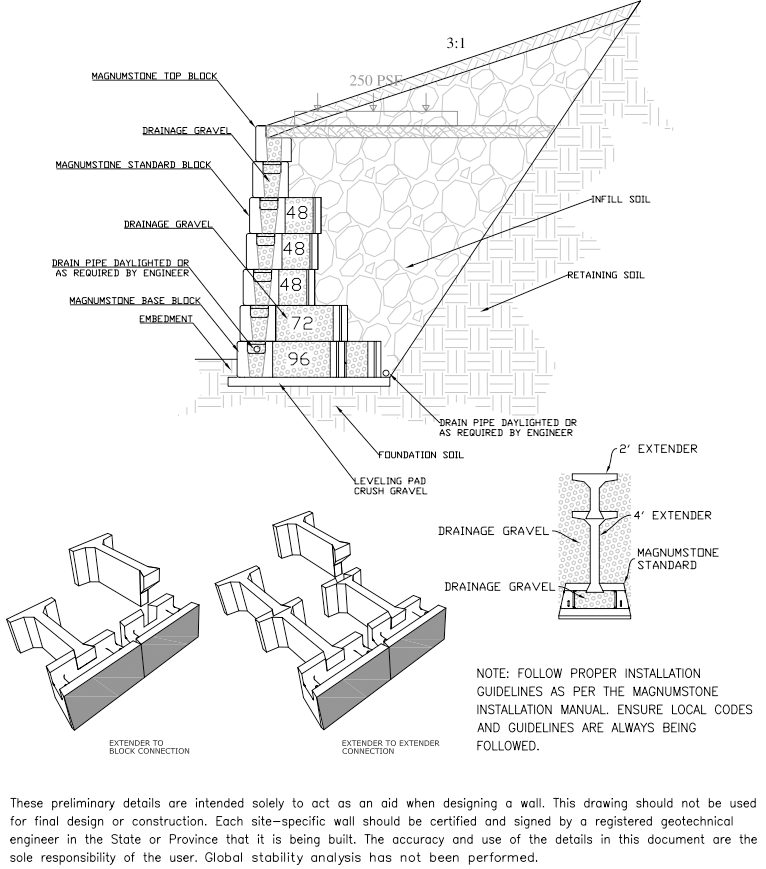

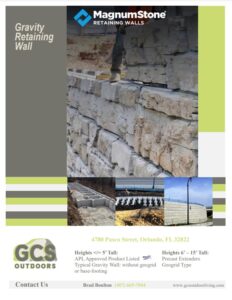

Your Gravity Wall just got taller

MagnumStone® Gravity Retaining Wall Extenders replace

Geogrid reinforcements by using a tongue-and-groove

concrete system to meet or exceed the demands of

engineers. This system reduces the massive footprint of

traditional cantilevered gravity retaining walls and gives

developers and owners greater use of land above the wall.

Geogrid reinforcements by using a tongue-and-groove

concrete system to meet or exceed the demands of

engineers. This system reduces the massive footprint of

traditional cantilevered gravity retaining walls and gives

developers and owners greater use of land above the wall.

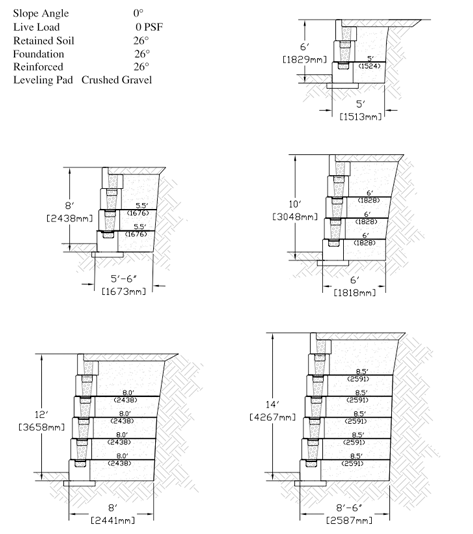

Gravity Extender Retaining Wall charts